User talk:Maddie

Carbon Model Development Solutions

Model Development - simple diffusion Build a simple model for carbon diffusion in silicon. Use a constant diffusivity: Dc = 1.0 * exp(-3.5 / kT) Set the initial carbon profile to: Cc = 1.0e18 * exp(- (x-0.1)*(x-0.1) / 0.001 ) + 1.0e15

Part 1: Diffuse the profile for 60min. at 900, 30min. at 1000, and 10min. at 1100C. Does it agree with what you expect from a simple estimated hand calculation?

Part 2: Modify the model so the diffusivity it proportional to carbon concentration / 1e16 . Run the same anneals – what happens qualitatively?

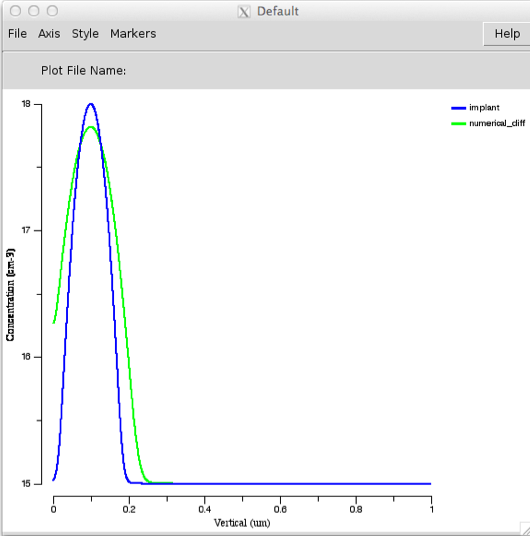

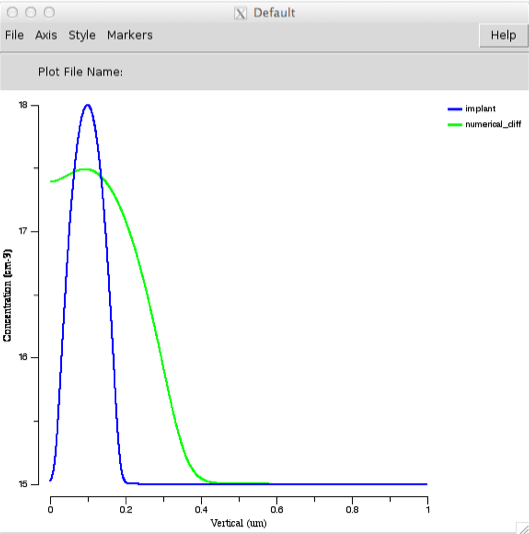

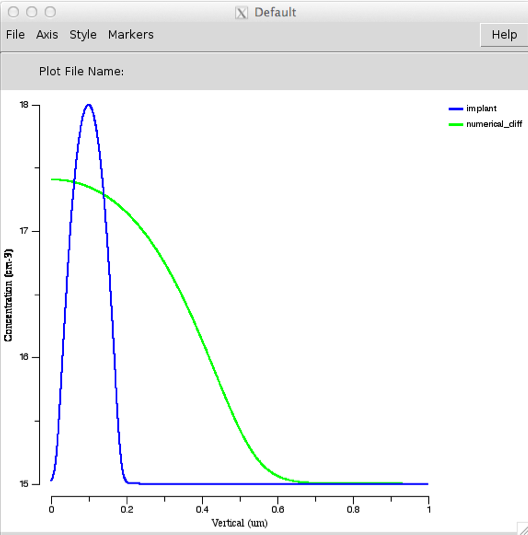

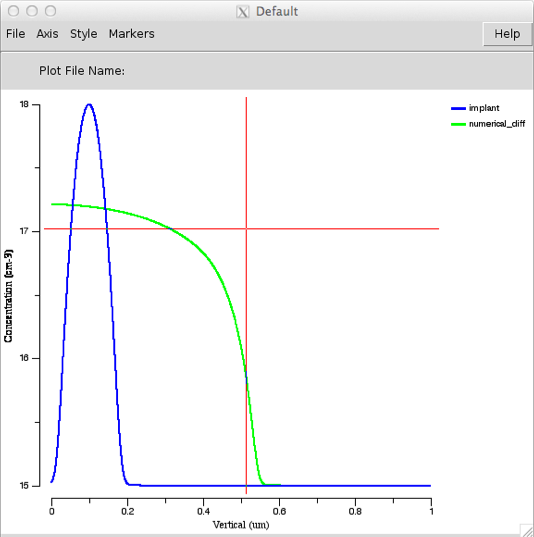

Results for Part 1:

At 900 Celsius for 60 mins:

At 1000 Celsius for 30 mins:

At 1100 Celsius for 10 mins:

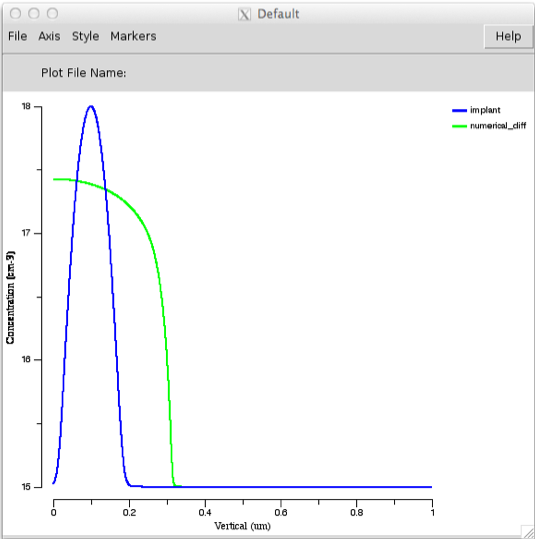

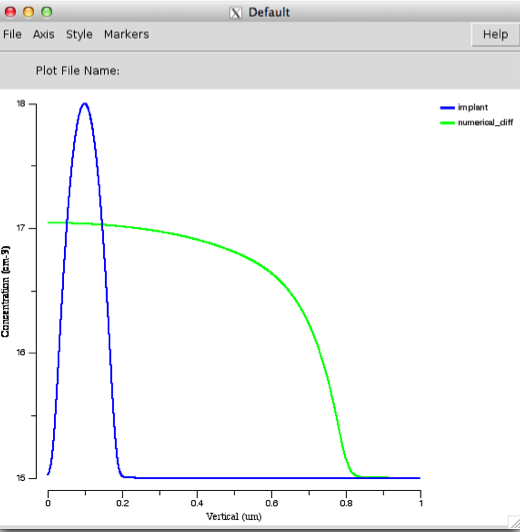

Results for Part 2:

At 900 Celsius for 60 mins:

At 1000 Celsius for 30 mins:

At 1100 Celsius for 10 mins:

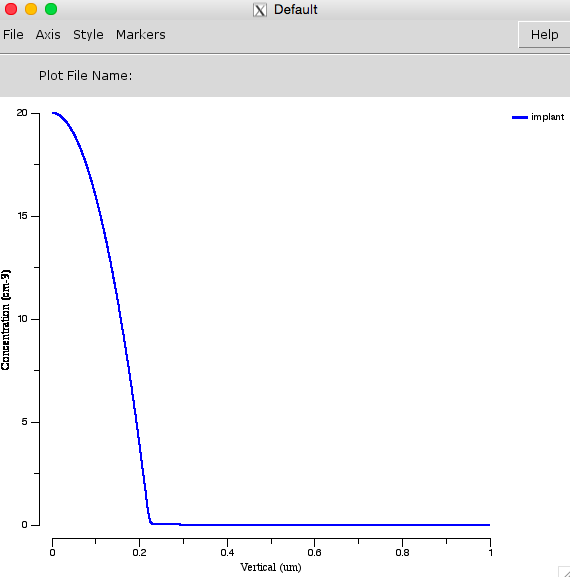

Simple Diode I-V Solutions

Diode - simple IV

FIRST: Build a one dimensional silicon diode with a constant p-type doping of 1e16 and an n-type Gaussian w/ peak concentration of 1.0e20 and a junction depth of 0.1um. Think carefully about the grid spacing needed to resolve the problem! Use constant mobility of 1000 for electrons and 200 for holes. Ignore recombination (for now).

CODE:

#establish diffusion parameters and solution variable "diode" DevicePackage math diffuse dim=1 umf none col !scale solution add name=diode solve !negative solution name=Potential nosolve solution add name=DevPsi solve negative damp solution add name=Elec solve !negative solution add name=Hole solve !negative

pdbSetDouble Silicon diode Abs.Error 1.0e-8 #absolute error range more important for quasi fermi levels pdbSetDouble Silicon diode Rel.Error 1.0e-2

#establish the grid and assign a material line x loc=0.0 spac=0.0002 tag=Top line x loc=1.0 spac=0.001 tag=Bottom region silicon xlo=Top xhi=Bottom init

#Gaussian implant profile #fill in the file name for as-implanted profile here sel z=1.0e20*exp(-(x)*(x)/(1.086e-3)) name=diode #plot the the as-implanted profile sel z=log10(abs(diode+1)) plot.1d label=implant

#setting the mobility and other variables

set eps [expr 11.8 * 8.854e-14 / 1.619e-19]

solution name=qfn add silicon const val= "DevPsi - 0.025*log(Elec/1.0e10)"

solution name=qfp add silicon const val= "0.025*log(Hole/1.0e10) + DevPsi"

set Emob "1000.0"; #/ (sqrt(1 + (200*diff(DevPsi)/1.0e7)^2))"

set Hmob "200.0"; #/ (sqrt(1 + (100*diff(DevPsi)/1.0e7)^2))"

set T 300.0

set k 1.38066e-23

set q 1.619e-19

set ni "1e10"

set Na "1.0e16"

set Nd "10"

set Vt "[expr {$k*$T/$q}]"

set ni "1.1e10"

#continuity equations set eqnP "$eps*grad(DevPsi)+Doping-Elec+Hole" set eqnE "ddt(Elec)-$Emob*0.025*sgrad(Elec, DevPsi/0.025)" set eqnH "ddt(Hole)-$Hmob*0.025*sgrad(Hole, -DevPsi/0.025)"

pdbSetDouble Si DevPsi DampValue 0.025 pdbSetDouble Si DevPsi Abs.Error 1.0e-9 pdbSetString Si DevPsi Equation $eqnP pdbSetString Si Elec Equation $eqnE pdbSetDouble Si Elec Abs.Error 1.0e-5 pdbSetString Si Hole Equation $eqnH pdbSetDouble Si Hole Abs.Error 1.0e-5

pdbSetDouble top Hole Abs.Error 1.0e-8 pdbSetDouble top Elec Abs.Error 1.0e-8 pdbSetDouble top DevPsi Abs.Error 1.0e-6 pdbSetDouble top Hole Rel.Error 1.0e-2 pdbSetDouble top Elec Rel.Error 1.0e-2 pdbSetDouble top DevPsi Rel.Error 1.0e-2

pdbSetDouble ReflectBottom Hole Abs.Error 1.0e-8 pdbSetDouble ReflectBottom Elec Abs.Error 1.0e-8 pdbSetDouble ReflectBottom DevPsi Abs.Error 1.0e-6 pdbSetDouble ReflectBottom Hole Rel.Error 1.0e-2 pdbSetDouble ReflectBottom Elec Rel.Error 1.0e-2 pdbSetDouble ReflectBottom DevPsi Rel.Error 1.0e-2

pdbSetBoolean top Elec Fixed 1

pdbSetBoolean top Hole Fixed 1

pdbSetBoolean top DevPsi Fixed 1

pdbSetBoolean top Elec Flux 1

pdbSetBoolean top Hole Flux 1

pdbSetBoolean top DevPsi Flux 1

pdbSetString top Elec Equation {Doping - Elec + Hole}

pdbSetString top Hole Equation {DevPsi + 0.025*log((Hole+1.0e-10)/1.0e10) - top}

pdbSetString top DevPsi Equation {DevPsi - 0.025*log((Elec+1.0e-10)/1.0e10) - top}

pdbSetDouble top Elec Flux.Scale 1.619e-19

pdbSetDouble top Hole Flux.Scale 1.619e-19

pdbSetBoolean ReflectBottom Elec Fixed 1 pdbSetBoolean ReflectBottom Hole Fixed 1 pdbSetBoolean ReflectBottom DevPsi Fixed 1 pdbSetBoolean ReflectBottom Elec Flux 1 pdbSetBoolean ReflectBottom Hole Flux 1 pdbSetBoolean ReflectBottom DevPsi Flux 1 pdbSetString ReflectBottom Hole Equation "Doping-Elec+Hole" pdbSetString ReflectBottom Elec Equation "DevPsi-0.025*log((Elec+1.0e-10)/1.0e10)" pdbSetString ReflectBottom DevPsi Equation "DevPsi+0.025*log((Hole+1.0e-10)/1.0e10)" pdbSetDouble ReflectBottom Elec Flux.Scale 1.619e-19 pdbSetDouble ReflectBottom Hole Flux.Scale 1.619e-19

line x loc=0.0 spac=.01 tag=Top line x loc=0.4 spac=0.001 line x loc=0.7 spac=0.001 line x loc=2.0 spac=0.01 tag=Bottom region silicon xlo=Top xhi=Bottom init

contact name=top silicon xlo=-0.1 xhi=0.1 add contact name=top voltage supply=0.0 #contact name=GND Silicon xlo=0.9 xhi=1.1 add sel z=1.0e21*(x<0.5)-1.0e17 name=Doping sel z=0.5*(Doping+sqrt(Doping*Doping+4.0e20))/1.0e10 name=arg sel z=0.025*log(arg) name=DevPsi sel z=1.0e10*exp(DevPsi/0.025) name=Elec sel z=1.0e10*exp(-DevPsi/0.025) name=Hole

device init; #saves old physics unless you have init

set plt [CreateGraphWindow]

contact name=top voltage supply = 1.0

device time=0.5e-10 movie = {

set time [simGetDouble Device time]

set cur [expr ([contact name=top sol=Elec flux] - [contact name=top sol=Hole flux])]

puts "$time $cur"

AddtoLine $plt 1.0IV $time $cur

}

puts $cur

SECOND:

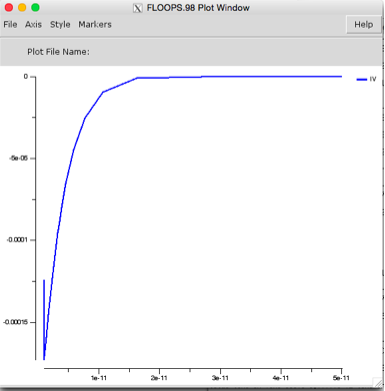

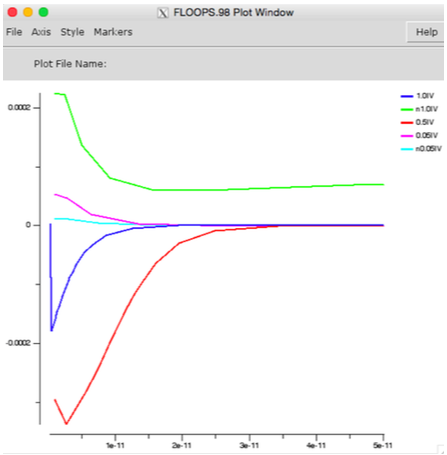

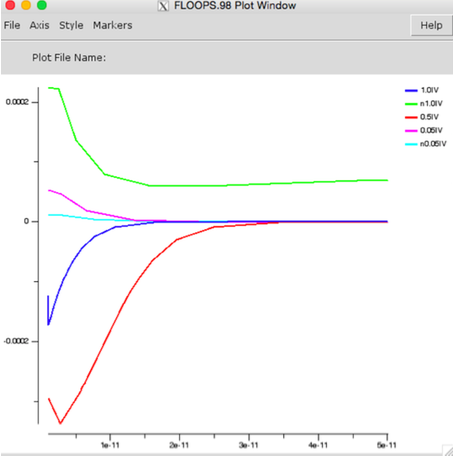

Implement a simple version of the three device equations and plot current v. voltage. Cut the grid spacing in half, and rerun the current / voltage plot. Does the current change appreciably? What does that say about the choice of grid?

Add a simple SRH recombination with carrier lifetimes of 1 nanosecond. Use 1.0e10 for the intrinsic carrier concentration. How does the reverse bias current change?

The Implant Profile does not change. However the transient plots are different. In the figures below, the blue lines are the reverse bias voltages. The lighter blue line is a smaller applied reverse bias with magnitude of 0.05 V whereas the darker blue line has a reverse bias magnitude of 1.0 V. In reverse bias, the model with shorter carrier lifetimes will have more recombination current and therefore a larger negative overall current, because more carriers can recombine rather then travel to the other end of the material. The difference between the two figures is difficult to see and the magnitudes of current is extremely small, but Figure 3 has a smaller negative overall current than Figure 2 because of the large difference in carrier lifetimes. After the current has reached its peak, the graph stabilizes to close to zero.

This project also experimented with different hole and electron carrier lifetimes (the lifetimes of the holes and electrons were not equal) and the results of the current versus time plots were similar to the larger lifetime behavior; smaller recombination current. This is believed to be true because its takes both particles to recombine and if some of the particles cannot recombine due to a longer lifetime, then the current of the recombination rate will be smaller, as if both carriers had longer lifetimes.

CODE:

#establish diffusion parameters and solution variable "diode"

DevicePackage

math diffuse dim=1 umf none col !scale

solution add name=diode solve !negative

solution name=Potential nosolve

solution add name=DevPsi solve negative damp

solution add name=Elec solve !negative

solution add name=Hole solve !negative

pdbSetDouble Silicon diode Abs.Error 1.0e-8

#absolute error range more important for quasi fermi levels

pdbSetDouble Silicon diode Rel.Error 1.0e-2

#establish the grid and assign a material

line x loc=0.0 spac=0.0002 tag=Top

line x loc=1.0 spac=0.001 tag=Bottom

region silicon xlo=Top xhi=Bottom

init

#Gaussian implant profile

#fill in the file name for as-implanted profile here

sel z=1.0e20*exp(-(x)*(x)/(1.086e-3)) name=diode

#plot the the as-implanted profile

sel z=log10(abs(diode+1))

plot.1d label=implant

#setting the mobility and other variables

set eps [expr 11.8 * 8.854e-14 / 1.619e-19]

solution name=qfn add silicon const val= "DevPsi - 0.025*log(Elec/1.0e10)"

solution name=qfp add silicon const val= "0.025*log(Hole/1.0e10) + DevPsi"

set Emob "1000.0"; #/ (sqrt(1 + (200*diff(DevPsi)/1.0e7)^2))"

set Hmob "200.0"; #/ (sqrt(1 + (100*diff(DevPsi)/1.0e7)^2))"

set T 300.0

set k 1.38066e-23

set q 1.619e-19

set ni "1e10"

set Na "1.0e16"

set Nd "10"

set Vt "[expr {$k*$T/$q}]"

set ni "1.1e10"

#SRH Recombination (Simplified) -

set tau_max_e 1.0e-5

set tau_max_h 3.0e-6

set Nref 1.0e16

#Doping Dependence

solution name=tau_n add silicon const val= "$tau_max_e/(1+((($Na+$Nd)/($Nref))))"

solution name=tau_p add silicon const val= "$tau_max_h/(1+((($Na+$Nd)/($Nref))))"

solution name=SRHrate add silicon const val= "((Elec*Hole)-(1.0e20))/((tau_p*(Elec+$ni))+(tau_n*(Hole+$ni)))"

#continuity equations

set eqnP "$eps*grad(DevPsi)+Doping-Elec+Hole"

set eqnE "ddt(Elec)-$Emob*0.025*sgrad(Elec, DevPsi/0.025)"

set eqnH "ddt(Hole)-$Hmob*0.025*sgrad(Hole, -DevPsi/0.025)"

pdbSetDouble Si DevPsi DampValue 0.025

pdbSetDouble Si DevPsi Abs.Error 1.0e-9

pdbSetString Si DevPsi Equation $eqnP

pdbSetString Si Elec Equation $eqnE

pdbSetDouble Si Elec Abs.Error 1.0e-5

pdbSetString Si Hole Equation $eqnH

pdbSetDouble Si Hole Abs.Error 1.0e-5

pdbSetDouble top Hole Abs.Error 1.0e-8

pdbSetDouble top Elec Abs.Error 1.0e-8

pdbSetDouble top DevPsi Abs.Error 1.0e-6

pdbSetDouble top Hole Rel.Error 1.0e-2

pdbSetDouble top Elec Rel.Error 1.0e-2

pdbSetDouble top DevPsi Rel.Error 1.0e-2

pdbSetDouble ReflectBottom Hole Abs.Error 1.0e-8

pdbSetDouble ReflectBottom Elec Abs.Error 1.0e-8

pdbSetDouble ReflectBottom DevPsi Abs.Error 1.0e-6

pdbSetDouble ReflectBottom Hole Rel.Error 1.0e-2

pdbSetDouble ReflectBottom Elec Rel.Error 1.0e-2

pdbSetDouble ReflectBottom DevPsi Rel.Error 1.0e-2

pdbSetBoolean top Elec Fixed 1

pdbSetBoolean top Hole Fixed 1

pdbSetBoolean top DevPsi Fixed 1

pdbSetBoolean top Elec Flux 1

pdbSetBoolean top Hole Flux 1

pdbSetBoolean top DevPsi Flux 1

pdbSetString top Elec Equation {Doping - Elec + Hole}

pdbSetString top Hole Equation {DevPsi + 0.025*log((Hole+1.0e-10)/1.0e10) - top}

pdbSetString top DevPsi Equation {DevPsi - 0.025*log((Elec+1.0e-10)/1.0e10) - top}

pdbSetDouble top Elec Flux.Scale 1.619e-19

pdbSetDouble top Hole Flux.Scale 1.619e-19

pdbSetBoolean ReflectBottom Elec Fixed 1

pdbSetBoolean ReflectBottom Hole Fixed 1

pdbSetBoolean ReflectBottom DevPsi Fixed 1

pdbSetBoolean ReflectBottom Elec Flux 1

pdbSetBoolean ReflectBottom Hole Flux 1

pdbSetBoolean ReflectBottom DevPsi Flux 1

pdbSetString ReflectBottom Hole Equation "Doping-Elec+Hole"

pdbSetString ReflectBottom Elec Equation "DevPsi-0.025*log((Elec+1.0e-10)/1.0e10)"

pdbSetString ReflectBottom DevPsi Equation "DevPsi+0.025*log((Hole+1.0e-10)/1.0e10)"

pdbSetDouble ReflectBottom Elec Flux.Scale 1.619e-19

pdbSetDouble ReflectBottom Hole Flux.Scale 1.619e-19

line x loc=0.0 spac=.01 tag=Top

line x loc=0.4 spac=0.001

line x loc=0.7 spac=0.001

line x loc=2.0 spac=0.01 tag=Bottom

region silicon xlo=Top xhi=Bottom

init

contact name=top silicon xlo=-0.1 xhi=0.1 add

contact name=top voltage supply=0.0

#contact name=GND Silicon xlo=0.9 xhi=1.1 add

sel z=1.0e21*(x<0.5)-1.0e17 name=Doping

sel z=0.5*(Doping+sqrt(Doping*Doping+4.0e20))/1.0e10 name=arg

sel z=0.025*log(arg) name=DevPsi

sel z=1.0e10*exp(DevPsi/0.025) name=Elec

sel z=1.0e10*exp(-DevPsi/0.025) name=Hole

device init; #saves old physics unless you have init

set plt [CreateGraphWindow]

contact name=top voltage supply = 1.0

device time=0.5e-10 movie = {

set time [simGetDouble Device time]

set cur [expr ([contact name=top sol=Elec flux] - [contact name=top sol=Hole flux])]

puts "$time $cur"

AddtoLine $plt 1.0IV $time $cur

}

puts $cur

#look into log plots

device init

contact name=top voltage supply = -1.0

device time=0.5e-10 movie = {

set time [simGetDouble Device time]

set cur [expr ([contact name=top sol=Elec flux] - [contact name=top sol=Hole flux])]

puts "$time $cur"

AddtoLine $plt n1.0IV $time $cur

}

device init

contact name=top voltage supply = 0.5

device time=0.5e-10 movie = {

set time [simGetDouble Device time]

set cur [expr ([contact name=top sol=Elec flux] - [contact name=top sol=Hole flux])]

puts "$time $cur"

AddtoLine $plt 0.5IV $time $cur

}

contact name=top voltage supply = 0.05

device time=0.5e-10 movie = {

set time [simGetDouble Device time]

set cur [expr ([contact name=top sol=Elec flux] - [contact name=top sol=Hole flux])]

puts "$time $cur"

AddtoLine $plt 0.05IV $time $cur

}

contact name=top voltage supply = -0.05

device time=0.5e-10 movie = {

set time [simGetDouble Device time]

set cur [expr ([contact name=top sol=Elec flux] - [contact name=top sol=Hole flux])]

puts "$time $cur"

AddtoLine $plt n0.05IV $time $cur

}